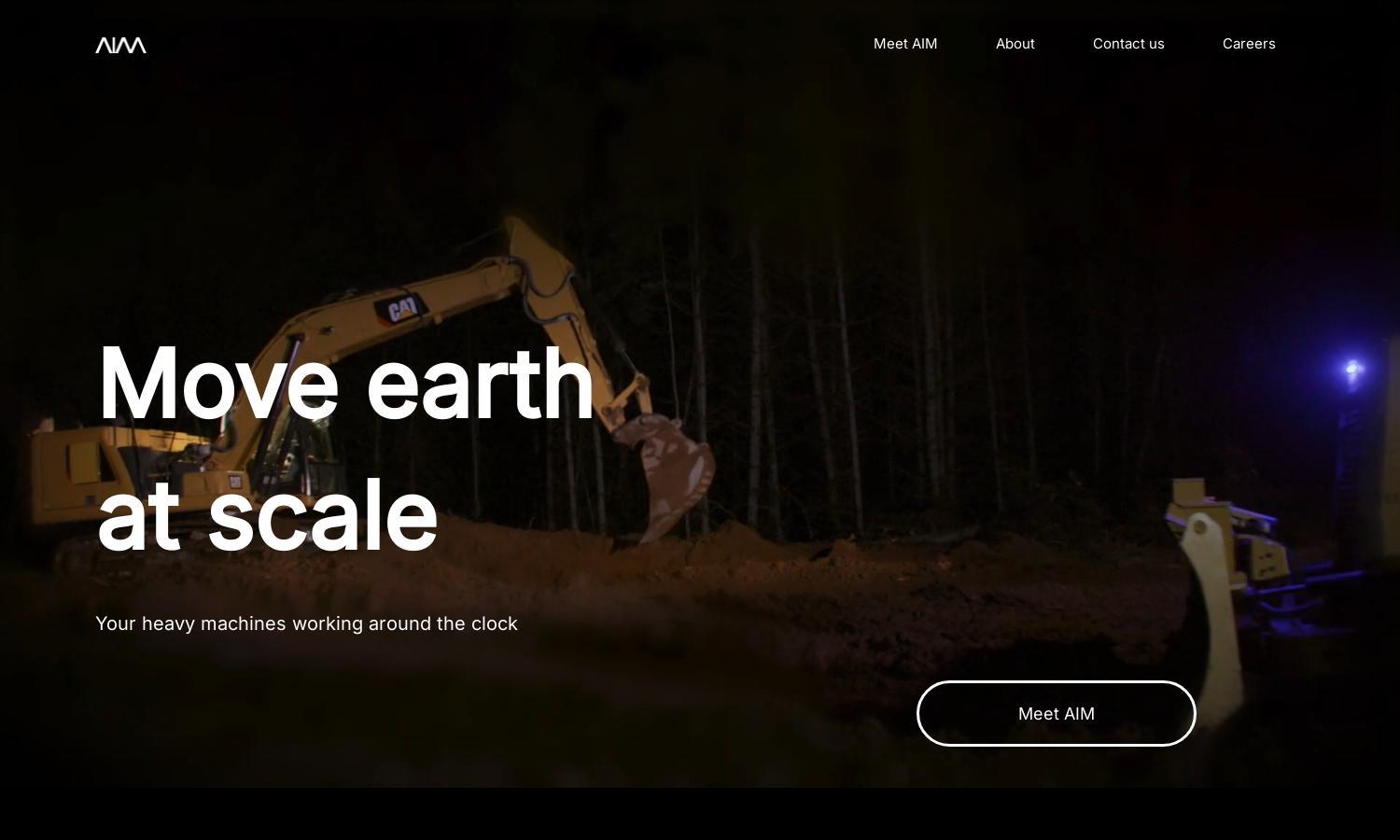

AIM Intelligent Machines

About AIM Intelligent Machines

AIM Intelligent Machines leverages advanced robotics and AI technology to automate heavy machinery for construction and mining industries. Tailored for enhancing safety and productivity, AIM transforms existing equipment into fully autonomous units without sacrificing manual operation capability. This innovative approach empowers businesses to maximize efficiency and minimize accidents.

AIM Intelligent Machines offers customized pricing plans that cater to various operational needs. Each tier delivers unique features and benefits, ensuring clients maximize their investment in autonomous machinery solutions. Upgrade options provide added support and services, enhancing overall safety and productivity, making AIM a vital partner in modernization.

AIM Intelligent Machines boasts a user-friendly interface designed for seamless navigation. The layout is intuitive, allowing easy access to features like machine automation and safety protocols. Unique functionalities, such as real-time monitoring and retrofitting capabilities, ensure an optimal browsing experience, positioning AIM as a leader in heavy machinery automation.

How AIM Intelligent Machines works

Users interact with AIM Intelligent Machines by first scheduling a consultation to discuss their specific equipment needs. Once onboarded, clients receive a tailored solution that retrofits their existing heavy machinery to enable autonomous operation. The platform offers user-friendly navigation to monitor equipment, manage safety protocols, and maximize operational efficiency sustainably.

Key Features for AIM Intelligent Machines

Autonomous Retrofitting

AIM Intelligent Machines enables autonomous retrofitting of existing heavy machinery. This unique feature allows clients to upgrade their equipment without the need for new investments, enhancing functionality while maintaining manual operation options. Users benefit from increased safety and productivity, making AIM essential for modern construction and mining operations.

360-Degree Safety Protocols

AIM Intelligent Machines implements 360-degree safety protocols that protect ground staff during autonomous operations. This key feature ensures comprehensive safety measures, preventing accidents and allowing machines to operate in hazardous environments without human exposure. Furthermore, it reassures clients of safe and efficient project completion, enhancing AIM's trustworthiness.

Expert Engineering Team

AIM Intelligent Machines is backed by a world-class engineering team specializing in robotics and advanced AI. Their expertise in developing autonomous solutions enhances the platform's innovative capabilities. Clients benefit from cutting-edge technology and industry experience, ensuring AIM delivers high-quality, safe, and efficient machine automation for construction and mining sectors.

You may also like: